Industrial hygiene assessments are vital in safeguarding the health of workers in environments where they may be exposed to poor conditions. These procedures are structured evaluations that identify, evaluate, and control risks associated with physical, chemical, biological, and ergonomic dangers in the workplace. By conducting regular industrial hygiene reviews, companies can ensure safer work environments, reduce health risks, and comply with regulatory standards. Here’s a closer look at the importance of industrial hygiene, hazardous materials assessments, and exploring professional assistance to see how they protect workers.

Identifying Workplace Hazards

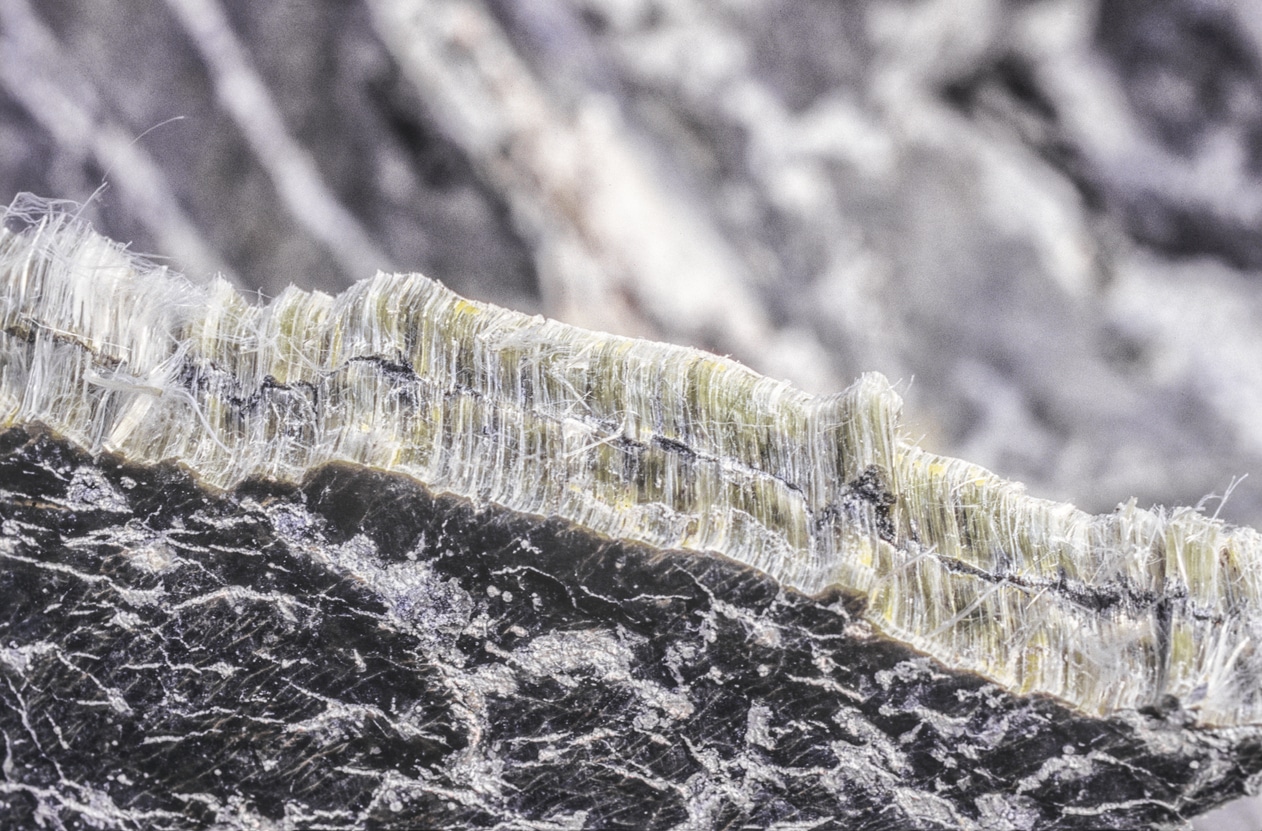

The primary purpose of an industrial hygiene assessment is to identify potential hazards in the workplace. These dangers can range from chemical exposure, like solvents and fumes, to physical dangers such as extreme temperatures, noise, and radiation. Hazardous materials consultants use specialized equipment to detect harmful substances in the air, monitor noise levels, and measure factors like humidity or lighting. By pinpointing these risks, companies can understand which aspects of their work environment pose health threats and require immediate attention.

Evaluating the Level of Exposure

Once hazards are identified, the next step is to assess the level of exposure workers face. Industrial hygienists determine the concentration of poisonous substances and compare them to recommended exposure limits. In cases involving chemicals, they may collect air samples or surface samples from various workstations. They’ll also evaluate factors such as how often workers interact with these dangers and how long they are exposed. This analysis helps prioritize which areas require the most urgent interventions to prevent serious health effects.

Implementing Control Measures

Control measures are essential to minimizing or eliminating workplace hazards, and industrial hygiene assessments guide these efforts. Controls can range from engineering changes, such as improved ventilation or equipment modifications, to administrative controls like reducing exposure times or rotating shifts. Where engineering controls aren’t sufficient, companies may introduce personal protective equipment (PPE), such as respirators, gloves, or ear protection. By tailoring control measures based on findings, companies can protect workers from harmful exposures and promote a healthier work environment.

Preventing Occupational Illness and Injury

Occupational illnesses like respiratory issues, hearing loss, and musculoskeletal disorders are preventable when dangers are adequately managed. Hazardous materials assessments help prevent these long-term health conditions by proactively addressing problems before they can cause harm. For instance, consistent monitoring of airborne contaminants can prevent respiratory diseases, while addressing noise can mitigate hearing loss risks. Reducing exposure not only protects workers but also reduces healthcare costs and improves productivity by keeping the workforce healthy.

Ensuring Compliance with Regulations

Industrial hygiene assessments are also crucial for regulatory compliance. In many countries, workplace safety regulations require companies to manage risks to worker health. For example, the Occupational Safety and Health Administration (OSHA) in the United States sets specific standards for exposure limits to chemicals and physical hazards. Industrial hygiene assessments are also crucial for regulatory compliance.

In many countries, workplace safety regulations require companies to manage risks to worker health. For example, the Occupational Safety and Health Administration (OSHA) in the United States sets specific standards for exposure limits to chemicals and physical hazards. For example, here in Alberta the Provincial Health and Safety Act outlines specific limits and requirements for employers to adhere to in identifying such hazards, in order to ensure the safety of their employees

Non-compliance with these regulations can lead to hefty fines and legal penalties. Regular assessments ensure that companies are meeting these standards, providing a secure workplace and avoiding costly violations.

Building a Culture of Safety

Beyond the technical aspects, industrial hygiene assessments contribute to fostering a culture of safety in the workplace. When employees see that their health and well-being are prioritized, it builds trust and boosts morale. Encouraging open communication about health and security and engaging workers in the process empowers them to voice concerns and participate in hazard identification. This proactive approach creates a more collaborative workplace where employees feel valued and protected.

Speak with a Hazardous Materials Consultant

Hazardous materials assessments are a cornerstone of workplace safety, especially in industries where poor conditions are a daily reality. By identifying dangers, evaluating exposure levels, implementing controls, and ensuring regulatory compliance, companies can protect their most valuable asset—their workers. A commitment to working with hazardous materials consultants on a regular basis not only prevents illness and injury but also strengthens workplace morale, productivity, and trust. Investing in these assessments is investing in the long-term health and success of both the workforce and the organization.

Alberta Safety & Environmental Services (ASE Services) is one of the most reputable providers of Hazardous materials assessment and hygiene inspection services—including asbestos, lead, mould, mercury, and silica detection, as well as industrial hygiene testing for grow ops and other facilities. With a background in Alberta’s Occupational Health & Safety Commission and professional project management skills, our qualified staff can provide reliable handling of air quality and industrial hygiene from initial industrial inspection all the way to remediation programs. Whether just for a permit, or in-depth air quality control, we can help. Feel free to reach out and secure air quality and hygiene requirements for your building.